Freight dimensioning

with CARGOMETER

The first dimensioning system

for moving forklifts

Freight dimensioning

with CARGOMETER

The first dimensioning system

for moving forklifts

Freight dimensioning

with CARGOMETER

The first dimensioning system

for moving forklifts

Freight dimensioning

with CARGOMETER

The first dimensioning system

for moving forklifts

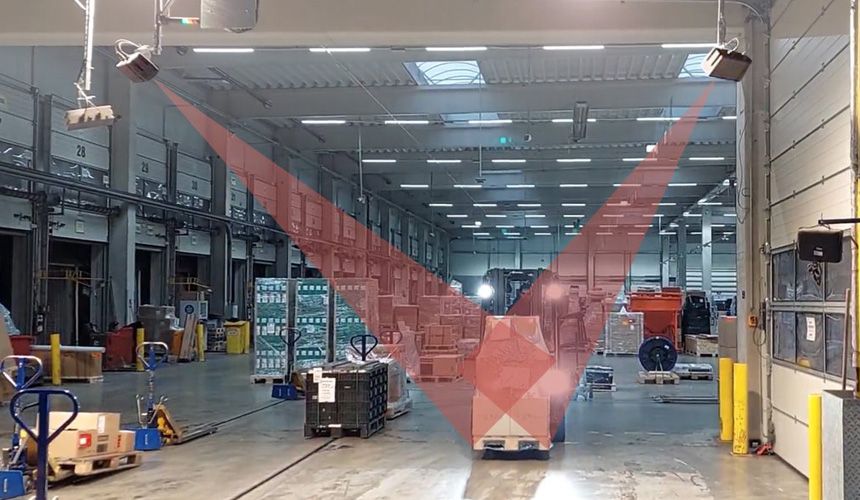

Dimension-in-Motion

… records the dimensions (length, width and height) and volume of each package up to a speed of 10 km/h.

Weigh-in-Motion

… uses forklift scales to weigh the freight during travel.

Scan-in-Motion

… replaces manual scanning of two-dimensional barcodes (e.g. QR codes) with fully-automatic recognition in motion.